Manufacturing that works

MRP + MES + PLM + Quality + Shop Floor + Maintenance

All you need in one single platform; fast and easy to use.

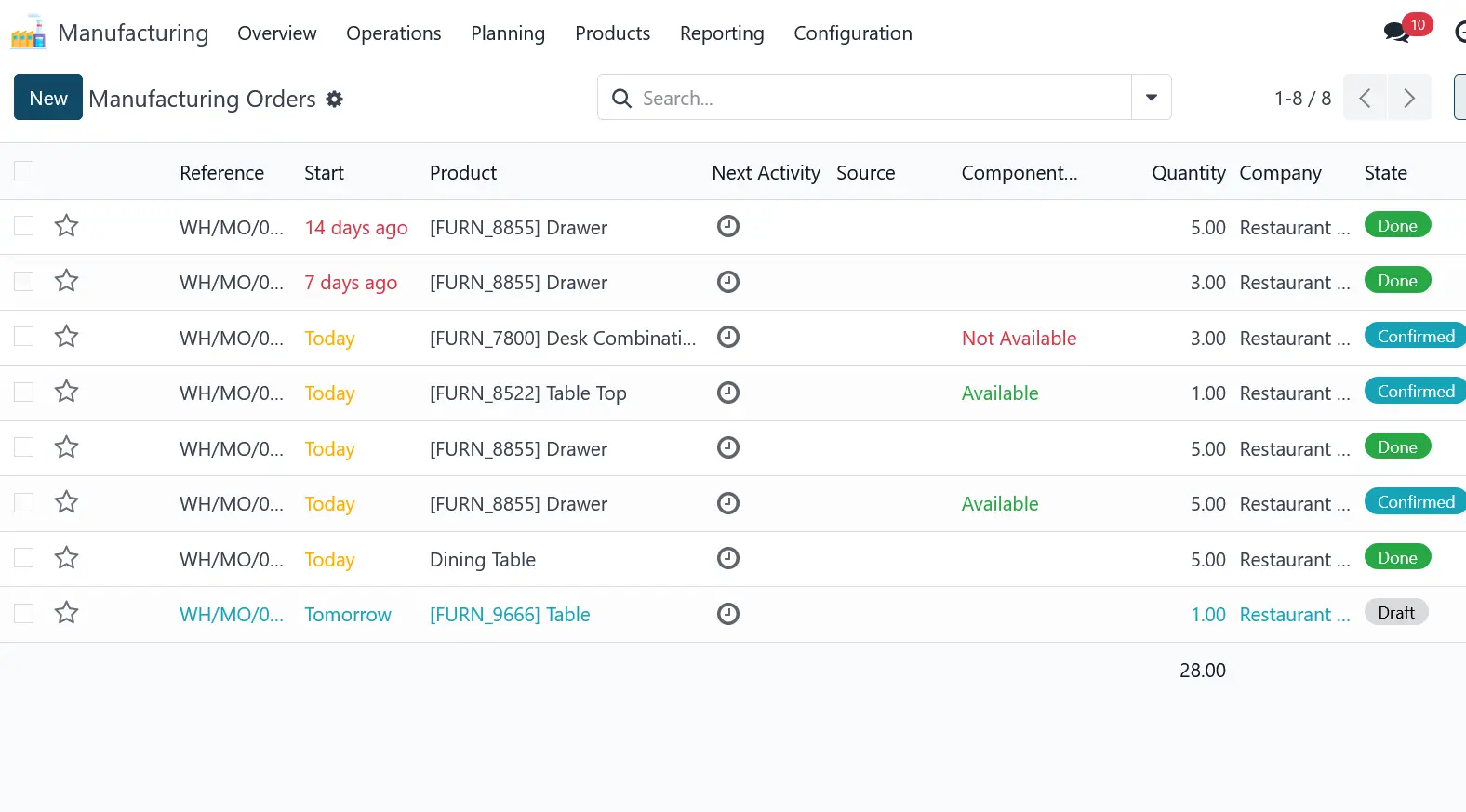

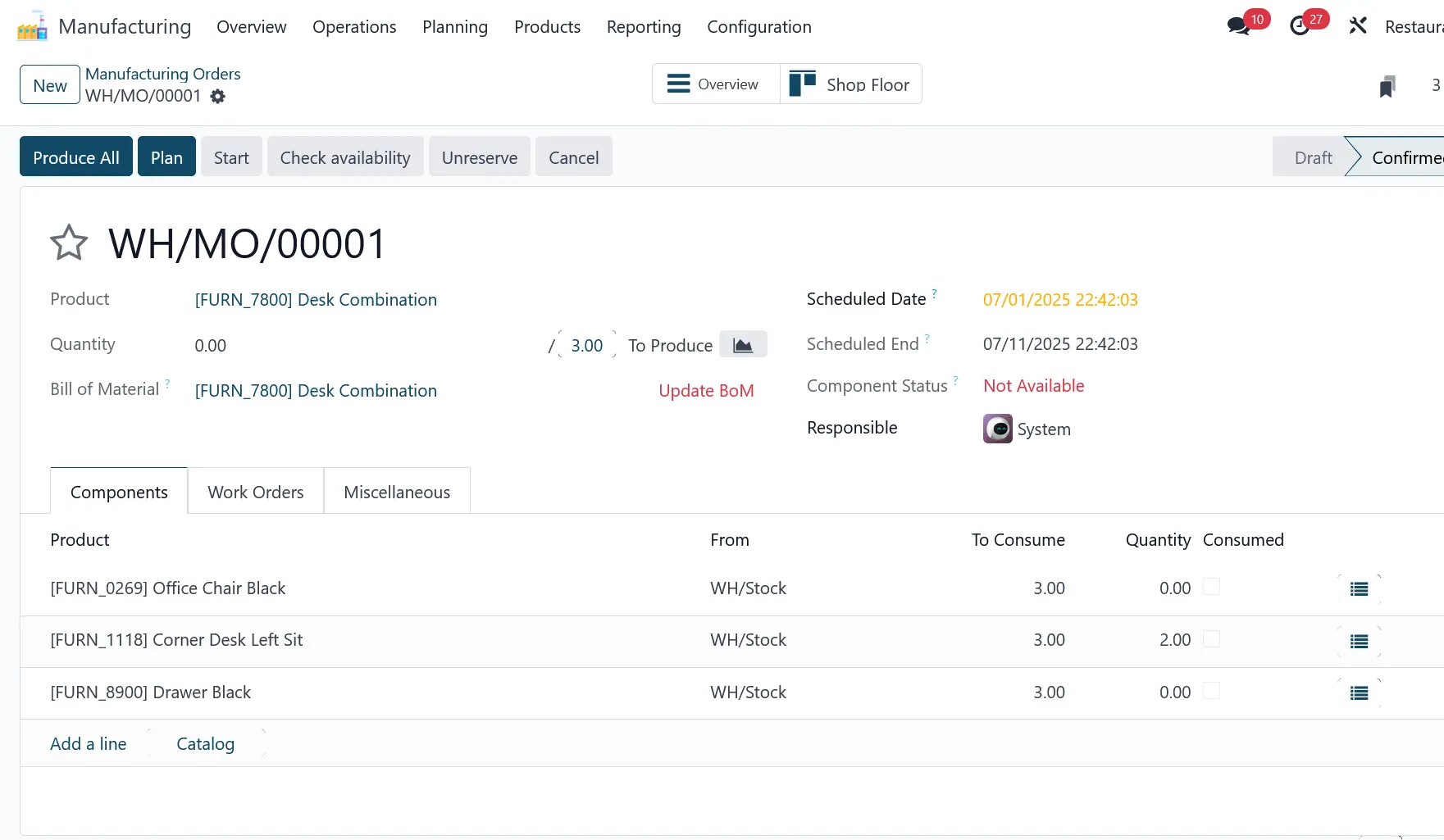

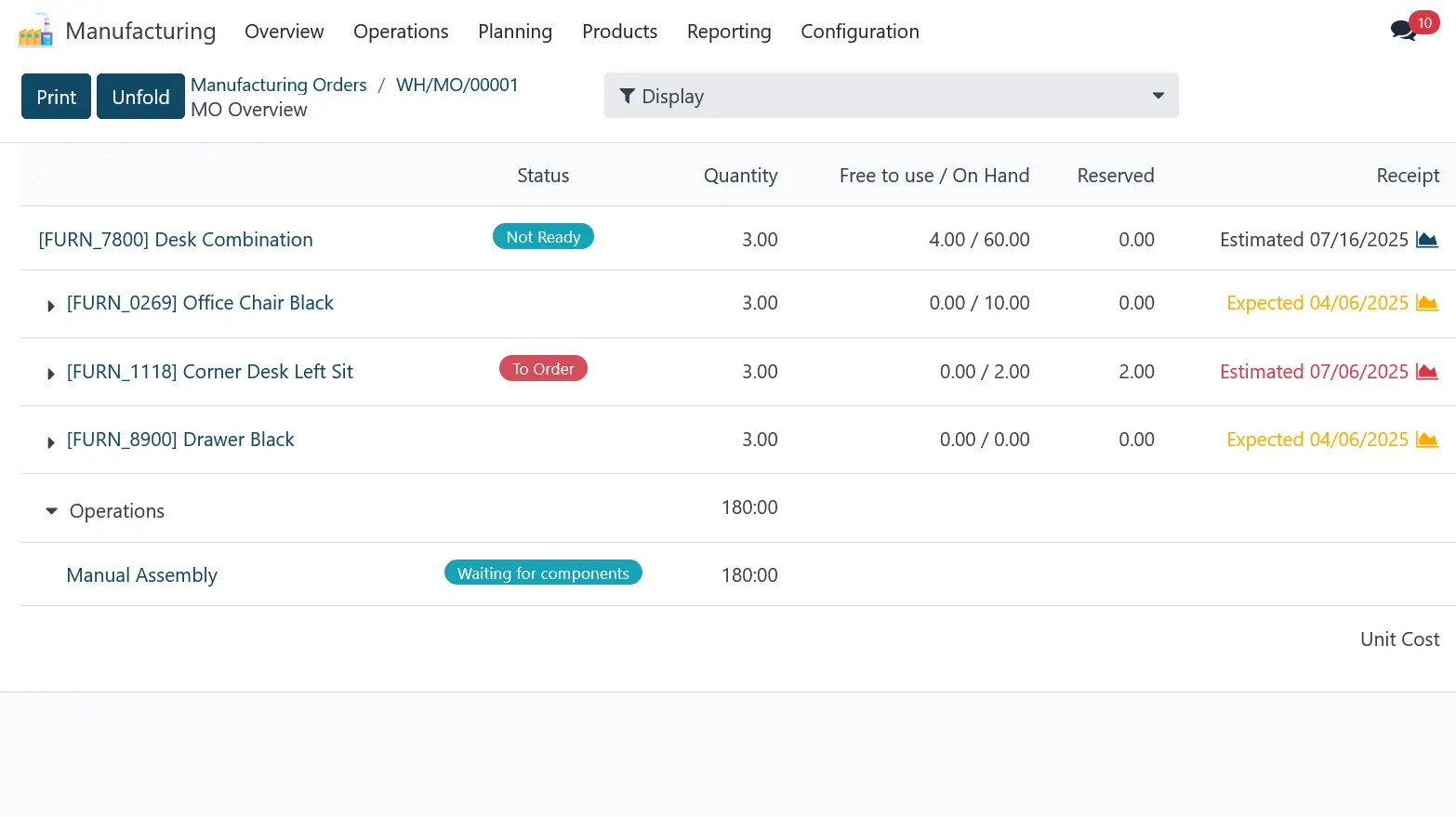

Real-time simulated operations

Simulate manufacturing orders with real-time capacity planning, component availability, and cost control.

Receive just-in-time replenishment suggestions and decide how to fulfill parts—whether to manufacture, purchase, subcontract, or transfer from another warehouse.

Planning that puts you ahead of schedule

Schedule manufacturing orders and plan resources with finite capacity planning.

Fine tune easily with the Gantt chart.

Record production and components

Use it to process orders, streamline operations, and minimize input errors. It works right out of the box—blazing fast and with zero latency.

Become a paperless company

The Shop Floor app streamlines your manufacturing line with a tablet-optimized dashboard.

Effortlessly manage workers, work centers, worksheets, quality checks, and more—all in one place.

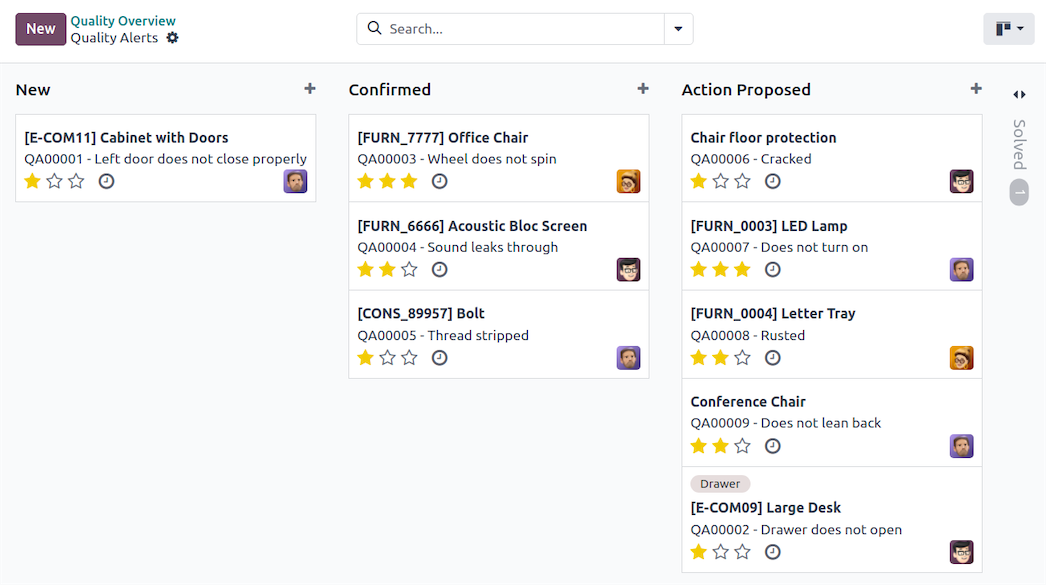

Get ready to reach Six Sigma Level 6 performance!

Gain statistical insights into quality issues and instantly set control points on the shop floor, complete with clear instructions.

Workers can easily provide feedback through the app whenever they spot waste in the manufacturing process. When ideas and information flow this seamlessly, quality reaches a whole new level.

Complete Manufacturing Suite

Everything you need for lean manufacturing in one platform

MRP (Material Requirements Planning)

Automated planning and scheduling with intelligent demand forecasting and inventory optimization.

MES (Manufacturing Execution System)

Real-time shop floor control with work order management and production tracking.

PLM (Product Lifecycle Management)

Complete product data management from design to retirement with version control.

Quality Management

Comprehensive quality control with inspection points, non-conformity tracking, and CAPA.

Shop Floor App

Mobile-first interface for operators with tablet optimization and offline capabilities.

Maintenance Management

Preventive and predictive maintenance scheduling with equipment tracking and costs.

Advanced Manufacturing Capabilities

Finite Capacity Scheduling

Advanced scheduling algorithms that consider real capacity constraints and resource availability.

IoT Integration

Connect your machines and sensors for real-time data collection and automated reporting.

Kanban and Lean Tools

Built-in lean manufacturing tools including Kanban boards, 5S audits, and waste tracking.

Cost Management

Real-time cost tracking with variance analysis and profitability insights per product.

Multi-Plant Management

Manage multiple manufacturing facilities with centralized planning and decentralized execution.

Analytics and Reporting

Advanced analytics with OEE calculation, performance dashboards, and custom reports.

An ideal solution for driving operational excellence

Transform your manufacturing operations with BridgeERP's comprehensive lean manufacturing platform. Reduce waste, improve quality, and increase efficiency across all your production processes.